Cenelec

H05VV-R & H05VV-U

Name in related standard

Sheathed cables for fixed wiring

Nominal Voltage U0/U

300/500V

Reference standard

IEC 60227-4

Standard code

60227 IEC 10

Tempreture range

– 30℃ to + 70℃

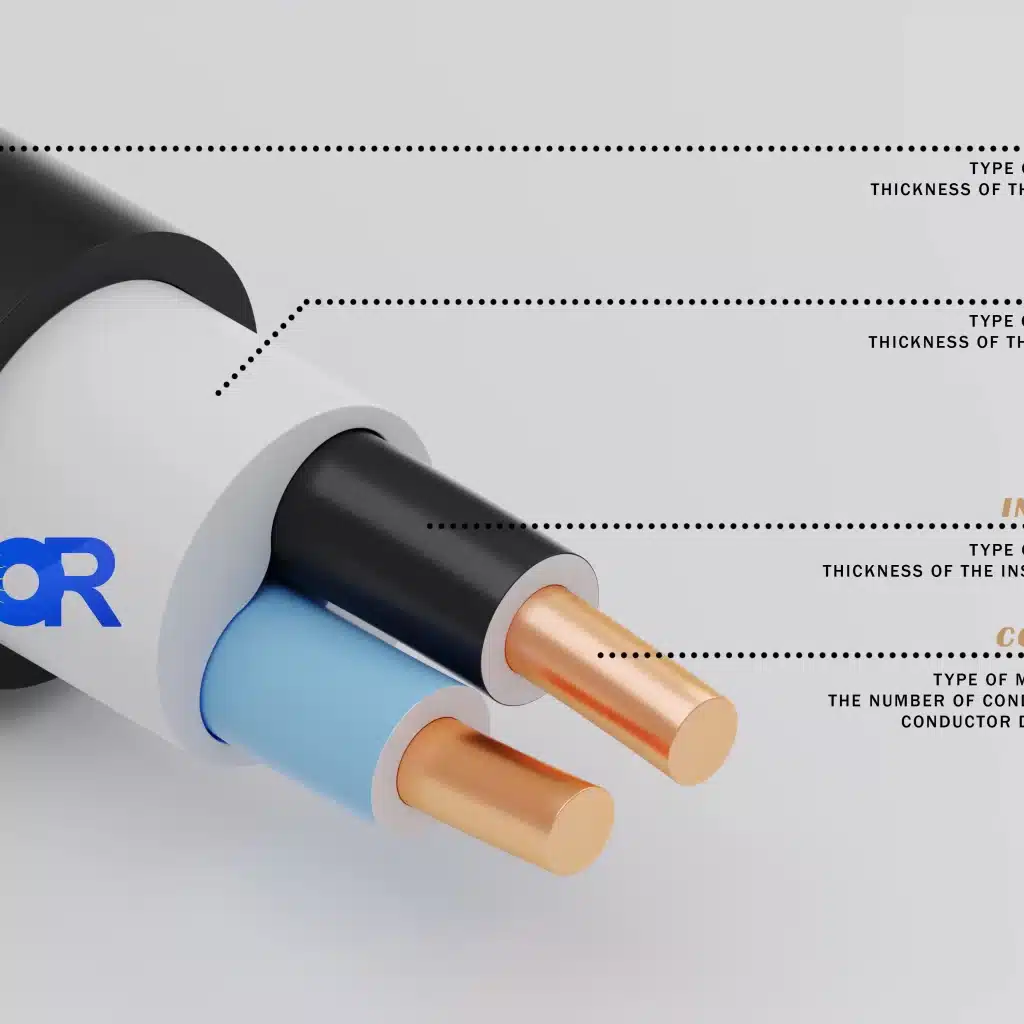

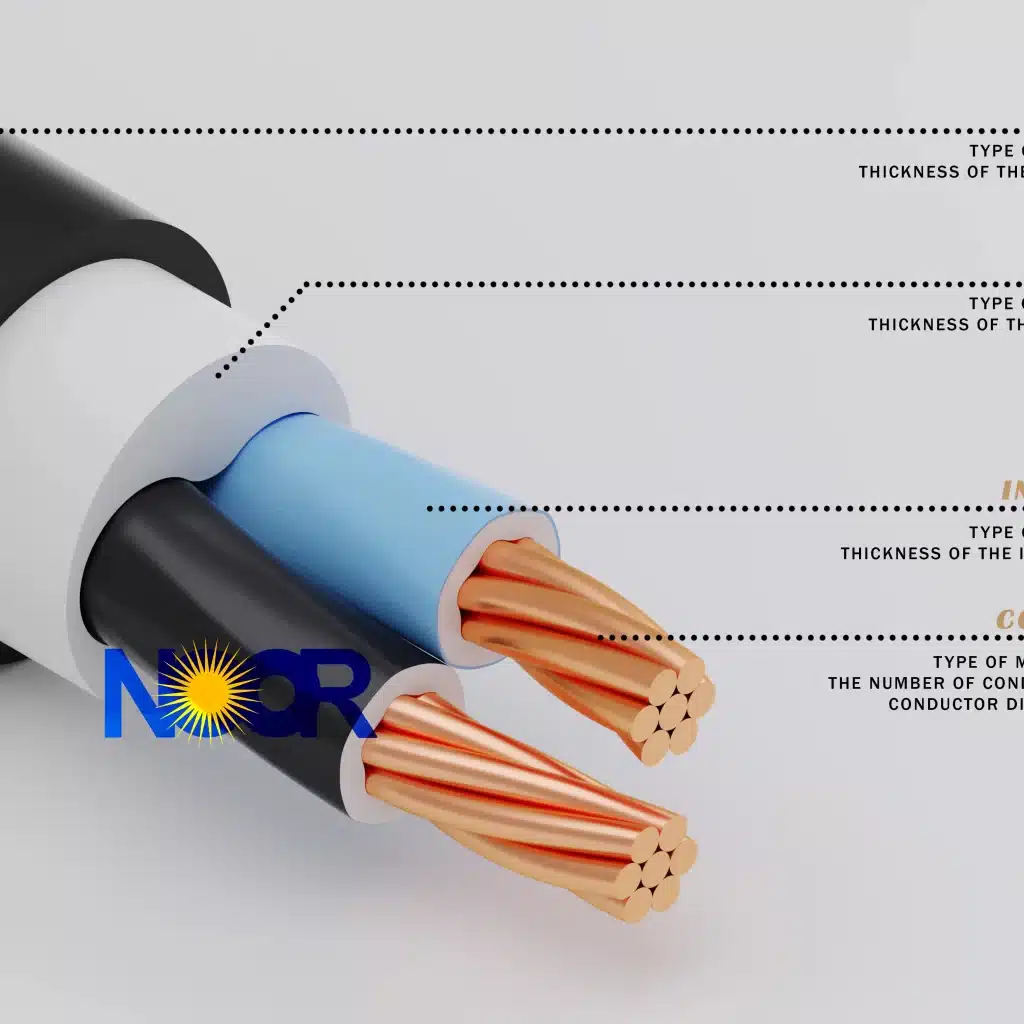

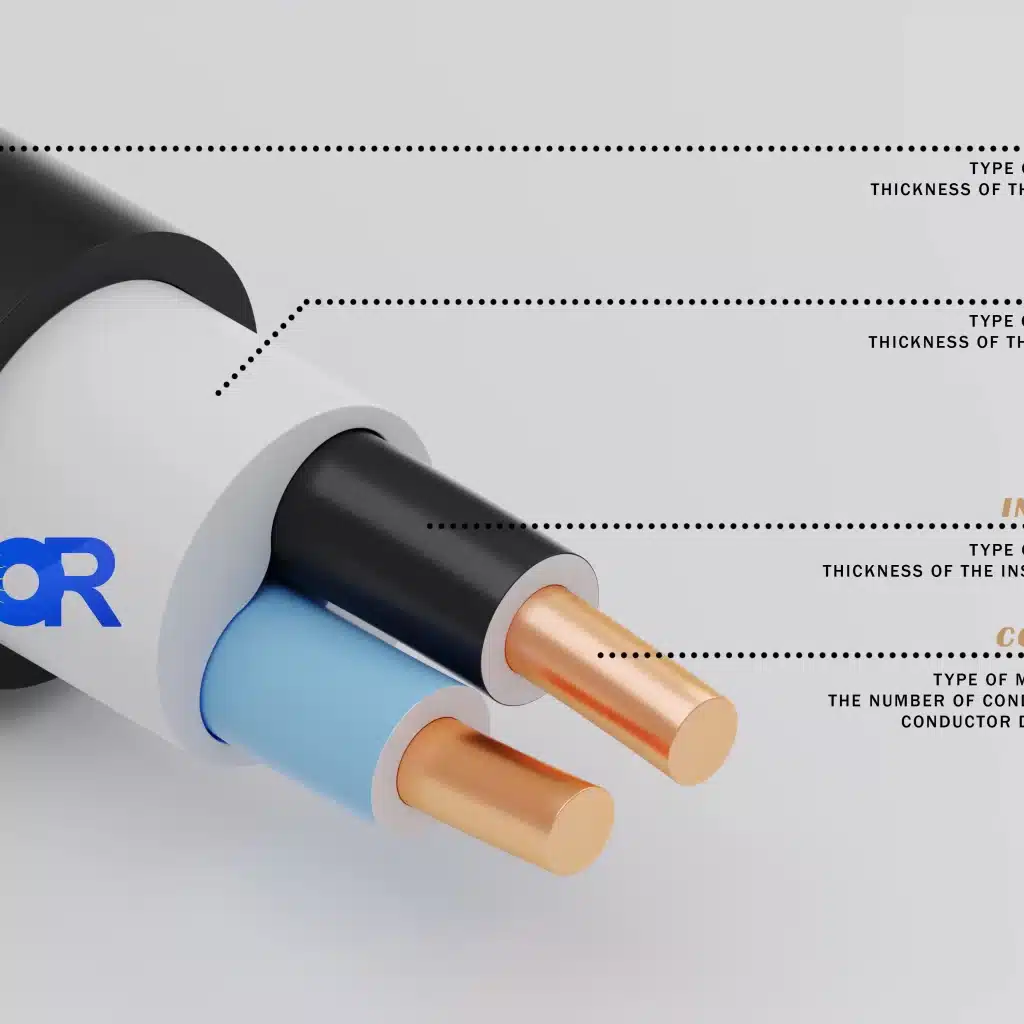

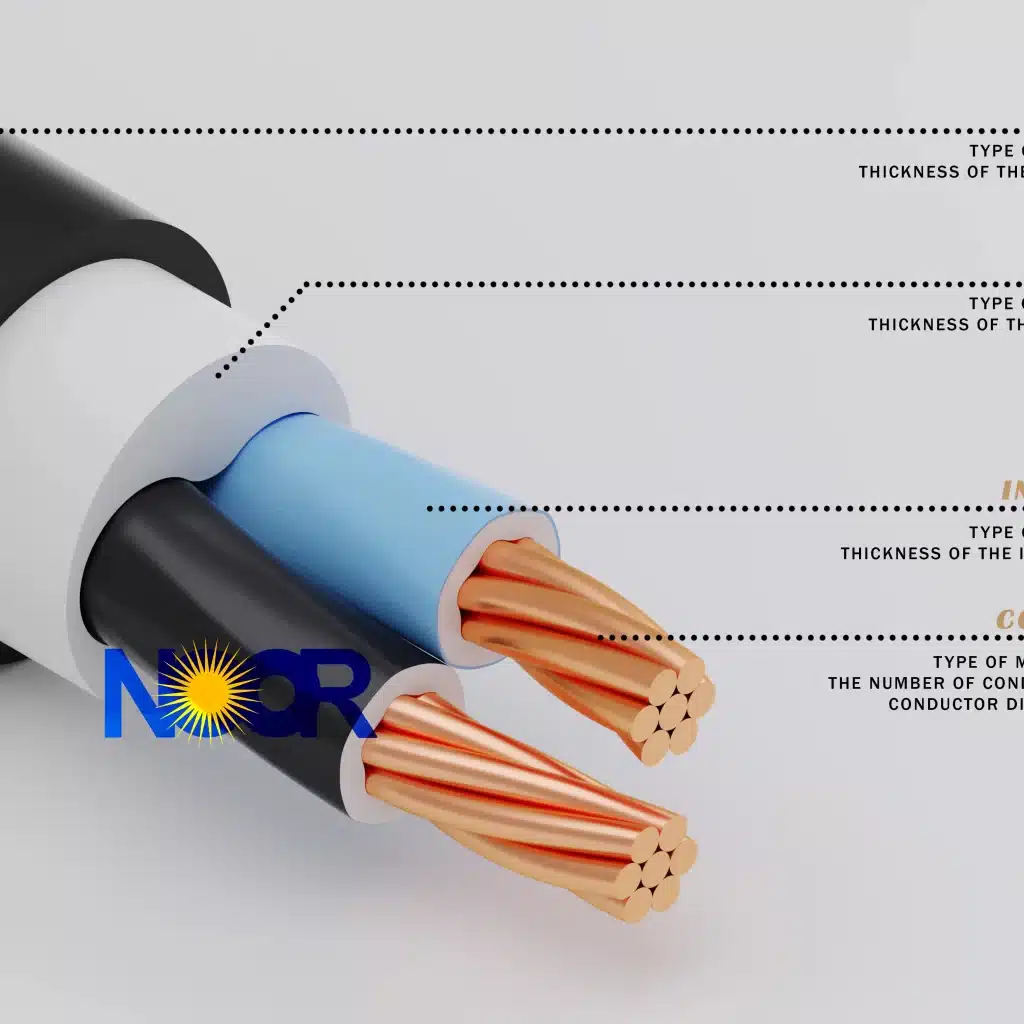

Cable Layer Construction

Cu/PVC/PVC

Conductor material

copper conductor according to IEC 60228, class 1( solid ) for conductors up to and including 16 mm², class 2 (stranded) for all sizes of conductors.

PVC core insulation

Compound type of PVC/ C.

PVC outer sheath

Compound type of PVC/ ST4.

Filler

PVC

Shield

*

Core insulation color

According to IEC 60227 – 1.

Sheath color

Sheath color is normally black.

1- These types of cables are used under or on plaster, on concrete or brick walls in dry or wet environments.

2-The use of these types of cables in external installations is allowed only if they are not exposed to direct sunlight.

3- These types of cables are not suitable for use in compressed concrete.

| Nominal cross section of conductors (mm²) | Conductor class | The number and diameter of the nominal string of conductors | Nominal insulation thickness (mm) | Approximate thickness of filler mm | Nominal sheath thickness (mm) | Average overall dimensions (Lower limit) (mm) | Average overall dimensions (Upper limit) (mm) | Maximum ohmic resistance of the conductor at 20°C (Ω/km) | Approximate (weight kg/km) |

|---|---|---|---|---|---|---|---|---|---|

| 2×1.5 | 1 | 1×1.33 | 0.7 | 0.6 | 1.2 | 7.6 | 10 | 12.1 | 115 |

| 2×1.5 | 2 | 7×0.52 | 0.7 | 0.6 | 1.2 | 7.8 | 10.5 | 12.1 | 124 |

| 2×2.5 | 1 | 1×1.74 | 0.8 | 0.6 | 1.2 | 8.6 | 11.5 | 7.41 | 155 |

| 2×2.5 | 2 | 7×0.66 | 0.8 | 0.6 | 1.2 | 9 | 12 | 7.41 | 169 |

| 2×4 | 1 | 1×2.19 | 0.8 | 0.6 | 1.2 | 9.6 | 12.5 | 4.61 | 200 |

| 2×4 | 2 | 7×0.82 | 0.8 | 0.6 | 1.2 | 10 | 13 | 4.61 | 220 |

| 2×6 | 1 | 1×2.76 | 0.8 | 0.6 | 1.2 | 10.5 | 13.5 | 3.08 | 260 |

| 2×6 | 2 | 7×1.01 | 0.8 | 0.6 | 1.2 | 11 | 14 | 1.08 | 285 |

| 2×10 | 1 | 1×3.51 | 1 | 0.7 | 1.4 | 13 | 16.5 | 1.83 | 430 |

| 2×10 | 2 | 7×1.33 | 1 | 0.7 | 1.4 | 13.5 | 17.5 | 1.83 | 455 |

| 2×16 | 2 | 7×1.7 | 1 | 0.7 | 1.4 | 15.5 | 20 | 1.15 | 630 |

| 2×25 | 2 | 7×2.12 | 1.2 | 1 | 1.4 | 18.5 | 24 | 0.727 | 960 |

| 2×35 | 2 | 7×2.46 | 1.2 | 1.1 | 1.6 | 21 | 27.5 | 0.524 | 1280 |

| 3×1.5 | 1 | 1×1.33 | 0.7 | 0.6 | 1.2 | 8 | 10.5 | 12.1 | 135 |

| 3×1.5 | 2 | 7×0.52 | 0.7 | 0.6 | 1.2 | 8.2 | 11 | 12.1 | 142 |

| 3×2.5 | 1 | 1×1.74 | 0.8 | 0.6 | 1.2 | 9.2 | 12 | 7.41 | 185 |

| 3×2.5 | 2 | 7×0.66 | 0.8 | 0.6 | 1.2 | 9.4 | 12.5 | 7.41 | 201 |

| 3×4 | 1 | 1×2.19 | 0.8 | 0.6 | 1.2 | 10 | 13 | 4.61 | 246 |

| 3×4 | 2 | 7×0.82 | 0.8 | 0.6 | 1.2 | 10.5 | 13.5 | 4.61 | 268 |

| 3×6 | 1 | 1×2.76 | 0.8 | 0.6 | 1.4 | 11.5 | 14.5 | 3.08 | 340 |

| 3×6 | 2 | 7×1.01 | 0.8 | 0.6 | 1.4 | 12 | 15.5 | 3.08 | 361 |

| 3×10 | 1 | 1×3.51 | 1 | 0.7 | 1.4 | 14 | 17.5 | 1.83 | 535 |

| 3×10 | 2 | 7×1.33 | 1 | 0.7 | 1.4 | 14.5 | 19 | 1.83 | 568 |

| 3×16 | 2 | 7×1.7 | 1 | 0.9 | 1.4 | 16.5 | 21.5 | 1.15 | 815 |

| 3×25 | 2 | 7×2.12 | 1.2 | 1 | 1.6 | 20.5 | 26 | 0.727 | 1230 |

| 3×35 | 2 | 7×2.46 | 1.2 | 1.1 | 1.6 | 22 | 29 | 0.524 | 1620 |

| 4×1.5 | 1 | 1×1.33 | 0.7 | 0.6 | 1.2 | 8.6 | 11.5 | 12.1 | 161 |

| 4×1.5 | 2 | 7×0.52 | 0.7 | 0.6 | 1.2 | 9 | 12 | 12.1 | 172 |

| 4×2.5 | 1 | 1×1.74 | 0.8 | 0.6 | 1.2 | 10 | 13 | 7.41 | 223 |

| 4×2.5 | 2 | 7×0.66 | 0.8 | 0.6 | 1.2 | 10 | 13.5 | 7.41 | 242 |

| 4×4 | 1 | 1×2.19 | 0.8 | 0.6 | 1.4 | 11.5 | 14.5 | 4.61 | 312 |

| 4×4 | 2 | 7×0.82 | 0.8 | 0.6 | 1.4 | 12 | 15 | 4.61 | 338 |

| 4×6 | 1 | 1×2.76 | 0.8 | 0.7 | 1.4 | 12.5 | 16 | 3.08 | 421 |

| 4×6 | 2 | 7×1.01 | 0.8 | 0.7 | 1.4 | 13 | 17 | 3.08 | 452 |

| 4×10 | 2 | 7×1.33 | 1 | 0.8 | 1.4 | 16 | 20.5 | 1.83 | 695 |

| 4×16 | 2 | 7×1.7 | 1 | 0.9 | 1.4 | 18 | 23.5 | 1.15 | 1000 |

| 4×25 | 2 | 7×2.12 | 1.2 | 1.1 | 1.6 | 22.5 | 28.5 | 0.727 | 1555 |

| 4×35 | 2 | 7×2.46 | 1.2 | 1.2 | 1.6 | 24.5 | 32 | 0.524 | 2010 |

| 5×1.5 | 1 | 1×1.33 | 0.7 | 0.6 | 1.2 | 9.4 | 12 | 12.1 | 187 |

| 5×1.5 | 2 | 7×0.52 | 0.7 | 0.6 | 1.2 | 9.8 | 12.5 | 12.1 | 202 |

| 5×2.5 | 1 | 1×1.74 | 0.8 | 0.6 | 1.2 | 11 | 14 | 7.41 | 266 |

| 5×2.5 | 2 | 7×0.66 | 0.8 | 0.6 | 1.2 | 11 | 14.5 | 7.41 | 280 |

| 5×4 | 1 | 1×2.19 | 0.8 | 0.7 | 1.4 | 12.5 | 16 | 4.61 | 384 |

| 5×4 | 2 | 7×0.82 | 0.8 | 0.7 | 1.4 | 13 | 17 | 4.61 | 415 |

| 5×6 | 1 | 1×2.76 | 0.8 | 0.8 | 1.4 | 13.5 | 17.5 | 3.08 | 510 |

| 5×6 | 2 | 7×1.01 | 0.8 | 0.8 | 1.4 | 14.5 | 18.5 | 3.08 | 540 |

| 5×10 | 1 | 1×3.51 | 1 | 0.8 | 1.4 | 17 | 21 | 1.83 | 782 |

| 5×10 | 2 | 7×1.33 | 1 | 0.8 | 1.4 | 17.5 | 22 | 1.83 | 830 |

| 5×16 | 2 | 7×1.7 | 1 | 1 | 1.6 | 20.5 | 26 | 1.15 | 1225 |

| 5×25 | 2 | 7×2.12 | 1.2 | 1.2 | 1.6 | 24.5 | 31.5 | 0.727 | 1860 |

| 5×35 | 2 | 7×2.46 | 1.2 | 1.3 | 1.6 | 27 | 35 | 0.524 | 2450 |

Cenelec

H05VV-R & H05VV-U

Name in related standard

Sheathed cables for fixed wiring

Nominal Voltage U0/U

300/500V

Reference standard

IEC 60227-4

Standard code

60227 IEC 10

Tempreture range

– 30℃ to + 70℃

Cable Layer Construction

Cu/PVC/PVC

Conductor material

copper conductor according to IEC 60228, class 1( solid ) for conductors up to and including 16 mm², class 2 (stranded) for all sizes of conductors.

PVC core insulation

Compound type of PVC/ C.

PVC outer sheath

Compound type of PVC/ ST4.

Filler

PVC

Shield

*

Core insulation color

According to IEC 60227 – 1.

Sheath color

Sheath color is normally black.

1- These types of cables are used under or on plaster, on concrete or brick walls in dry or wet environments.

2-The use of these types of cables in external installations is allowed only if they are not exposed to direct sunlight.

3- These types of cables are not suitable for use in compressed concrete.

[ninja_tables id=”18811″]